About Our Company

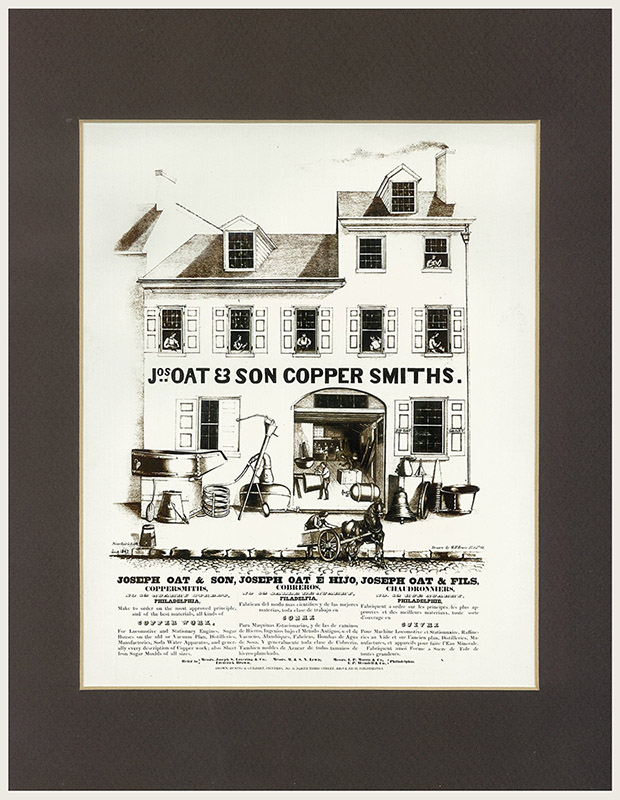

Joseph Oat Corporation, a name synonymous with pressure vessel and heat exchanger quality and reliability for many decades, is conveniently located on the Delaware River in Camden, New Jersey, directly across the river from Philadelphia, Pennsylvania. Our deep water port location allows us to economically ship equipment worldwide. In addition, our facility is readily accessible by rail and truck for shipments anywhere within North America.

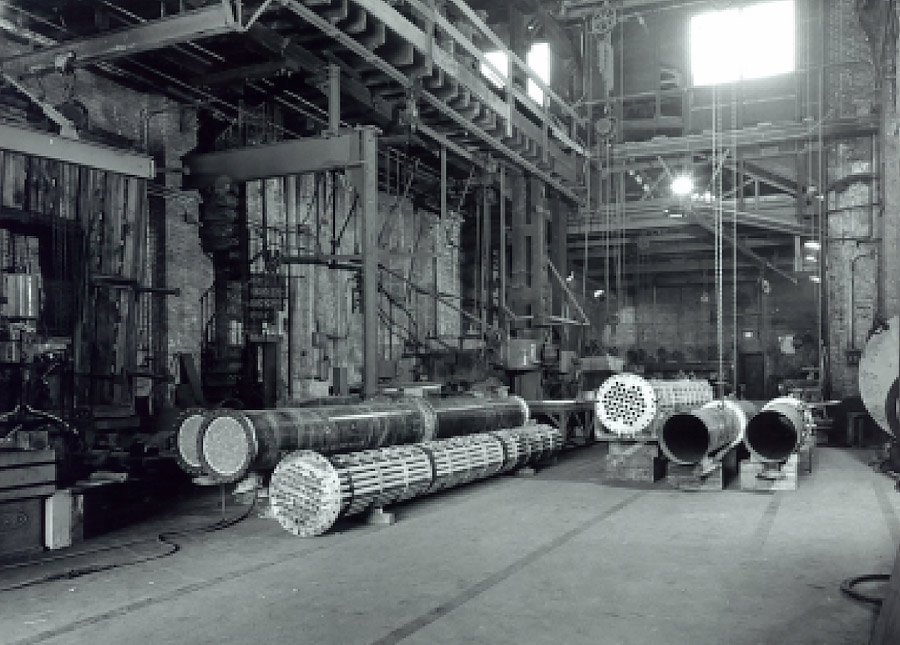

Joseph Oat Corporation’s plant consists of 120,000 sq. ft. (11,150 sq. M) of manufacturing space, with 60 ft. clearance under the crane hook. Capable of lifts exceeding 160 tons, our shop can fabricate immense and complex vessels and weldments, or can manufacture small and very tight tolerance equipment for specialized services. Most equipment we produce is designed and fabricated in accordance with ASME Code standards, including ASME Section I, Section III (Class 1, 2, and 3), and Section VIII Div 1 and 2. Included in our facility is a 20,000 sq. ft. (1860 sq. M) segregated room which can function as a fully enclosed and ventilated clean room for the fabrication of reactive metal equipment such as titanium and zirconium. The clean room is also utilized for certain specialized fabrications where segregation of corrosion resistant material away from carbon steel is critical.

Joseph Oat is a technology leader. Our expertise in heat transfer technology has provided many customers with innovative and economically viable solutions to their specific problems. In addition to being licensees of HTRI™ and AspenTech™ software, we perform beta testing on this software and provide input through various communications committees as well. Our charter membership and leadership role in TEMA assures that we will remain influential in heat exchanger design technology now and in the future. In addition to performing mechanical and thermal rating of heat exchangers, Joseph Oat also performs seismic analysis and finite element analysis on pressure vessels of all types when required by customer specification. All of our customers benefit by our sophisticated Quality Assurance Program. This Program is structured to comply with the most stringent federal and ASME Code nuclear quality assurance standards, as well as international standards of quality, including ISO 9001. Our many years of experience in providing safety related equipment and equipment for severe industrial applications have given us a unique perspective on the relationship between an effective quality program and the consistent quality of our products and services themselves.

The combination of Joseph Oat’s deep experience and sufficient size enables us to tackle the largest and most challenging projects, yet Joseph Oat is small enough to provide the buyer with a true sense of old-fashioned service. Our employees are the key to our success and strength. We are not a company managed by a corporate conglomerate. Our owners work side by side with our employees and deliver a level of service that is uncommon in this industry and is highly valued by our customers. Even as a small business, we can do big things for our customers.

For more information, we invite you to review areas of specific interest within our website, and we ask that you provide us with feedback or questions you may have regarding our services.