Design

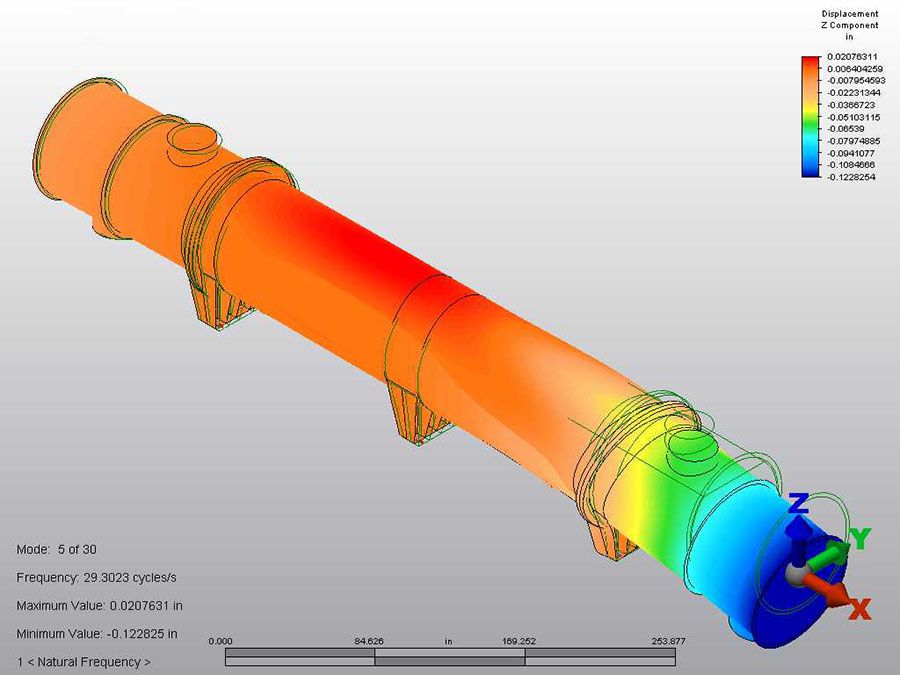

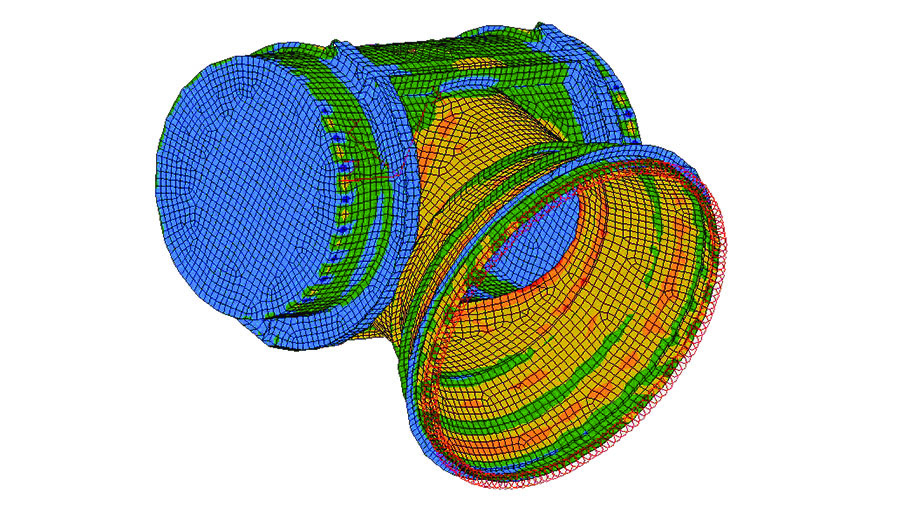

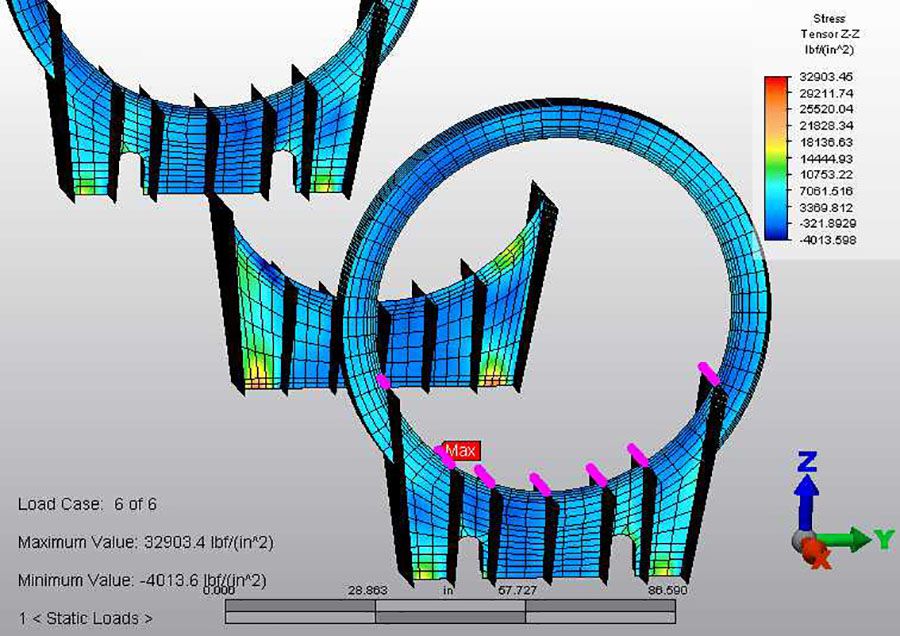

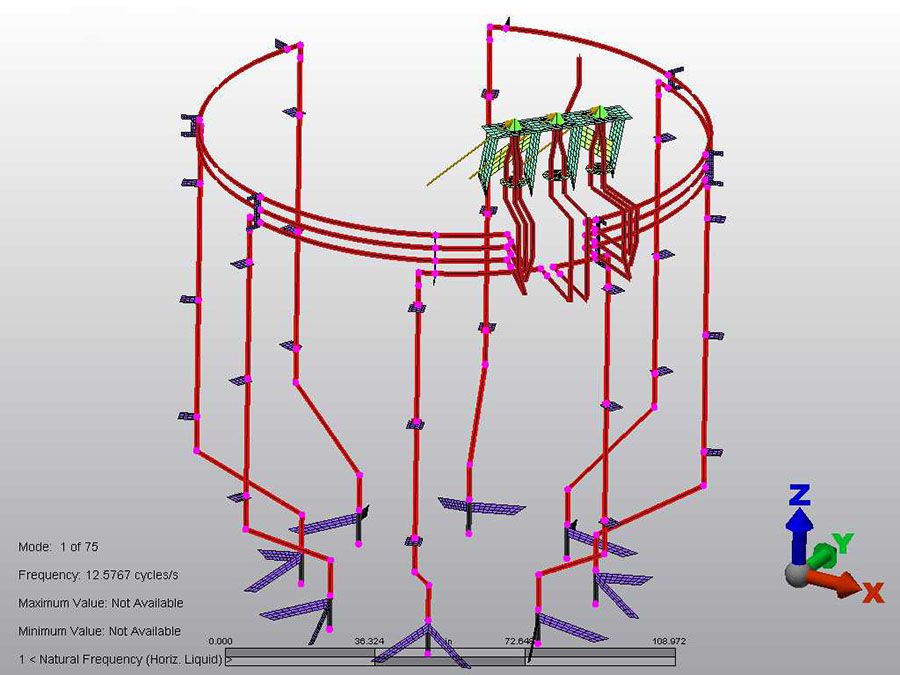

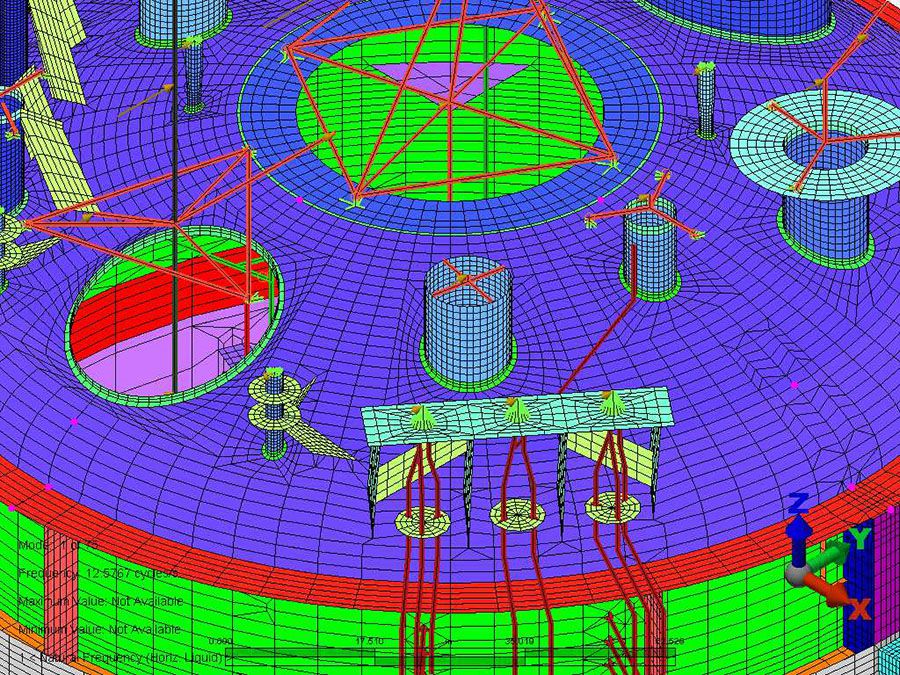

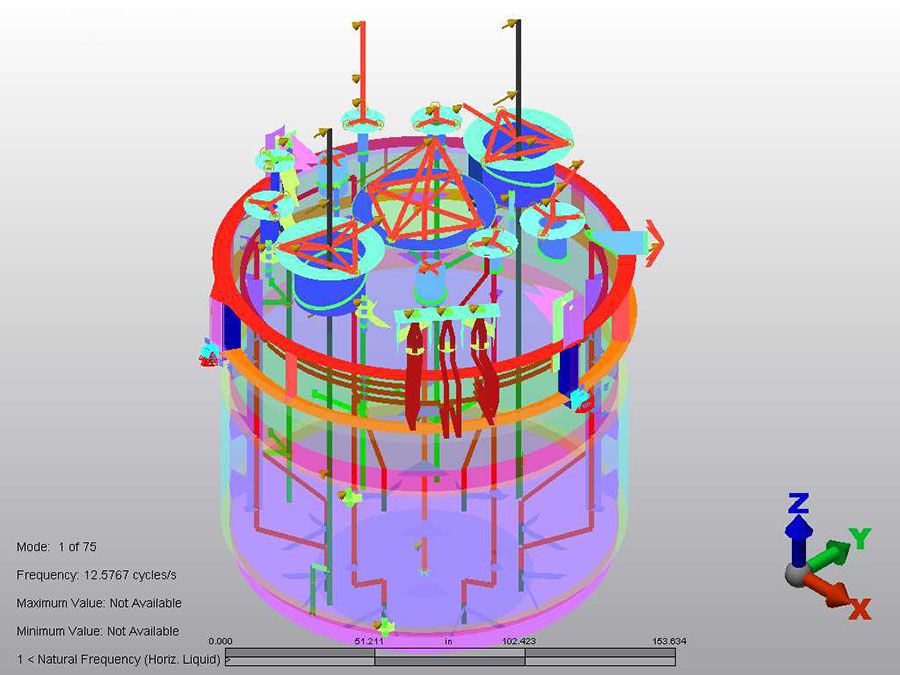

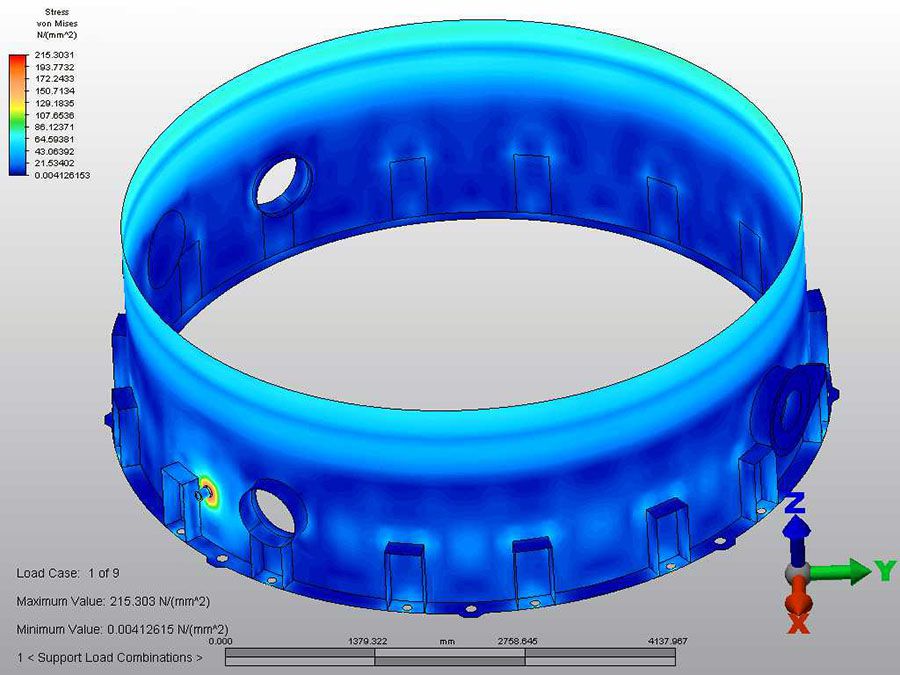

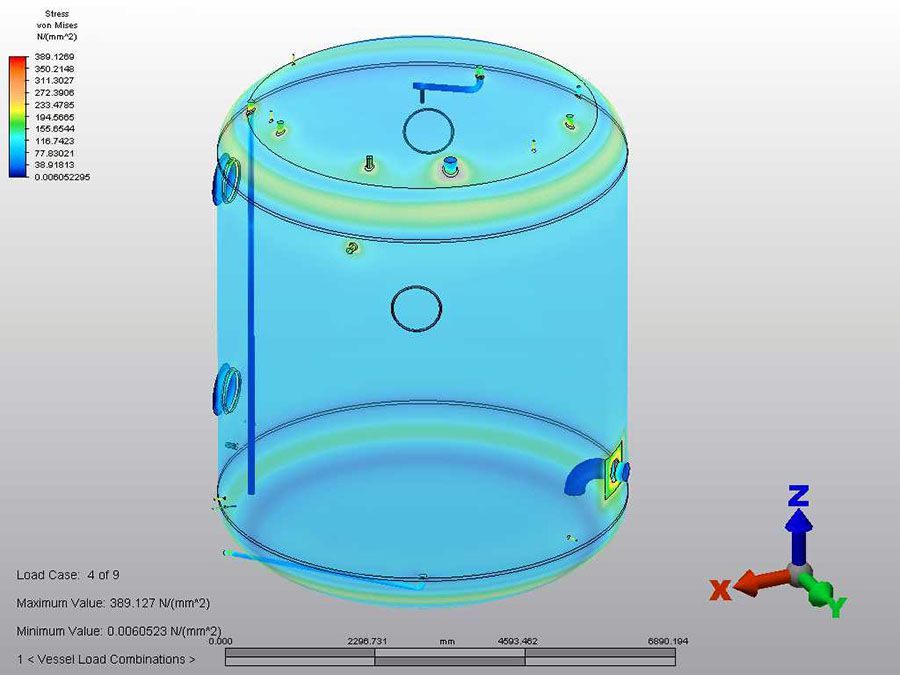

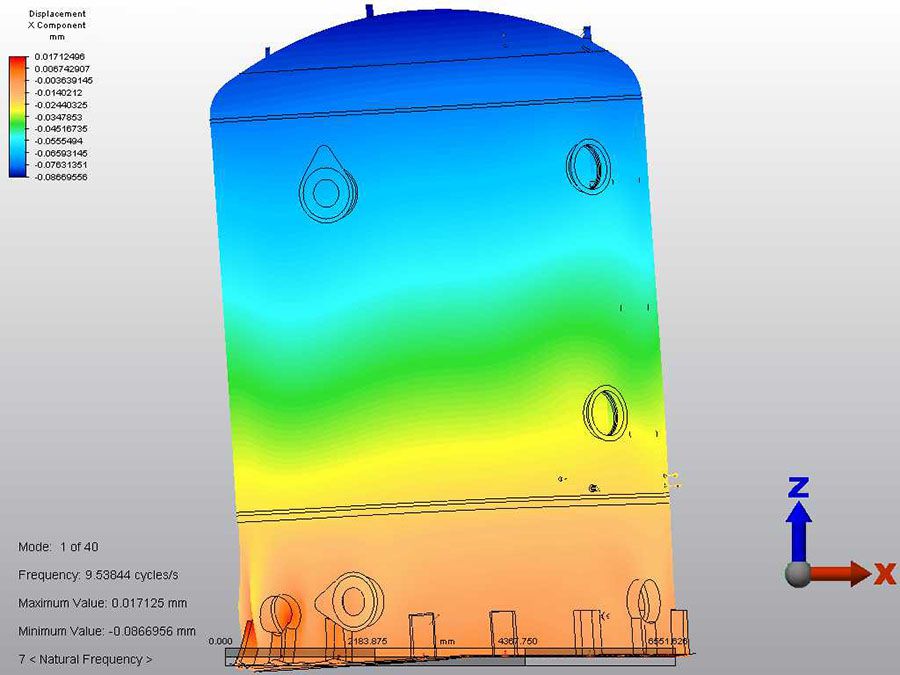

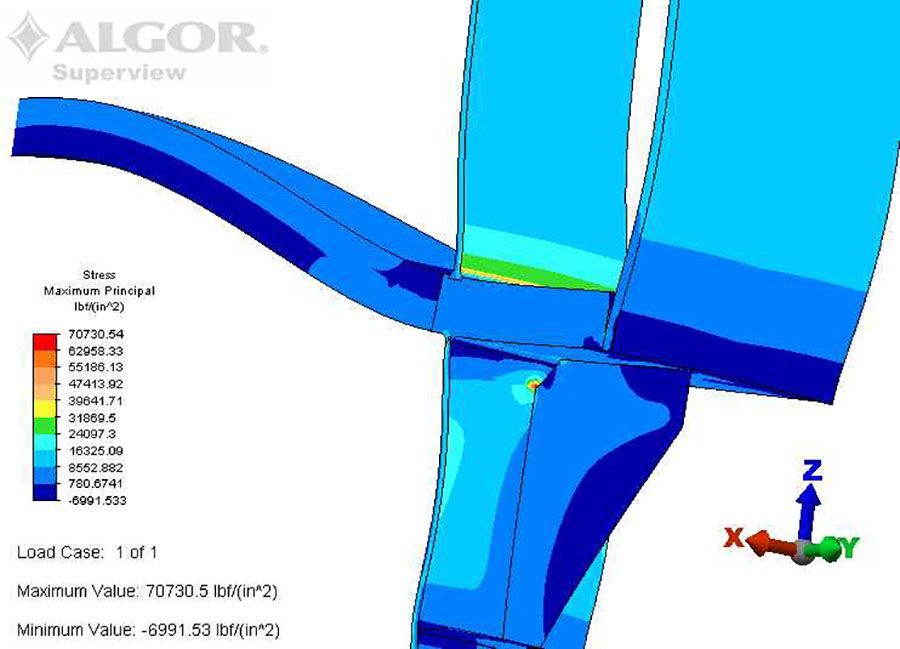

Joseph Oat Engineers are qualified to design the custom pressure equipment you need to perform under demanding conditions. Our design capabilities arise from decades of experience with the ASME Boiler & Pressure Vessel Codes, thermal/hydraulic/vibration design of shell and tube heat exchangers, and analysis of custom structures under multiple loadings. Joseph Oat designs utilize modern fabrication techniques, knowledge of commercially available materials, and consideration of operation and maintenance requirements to bring you economical, high quality pressure vessels for any application.

Joseph Oat Engineers …

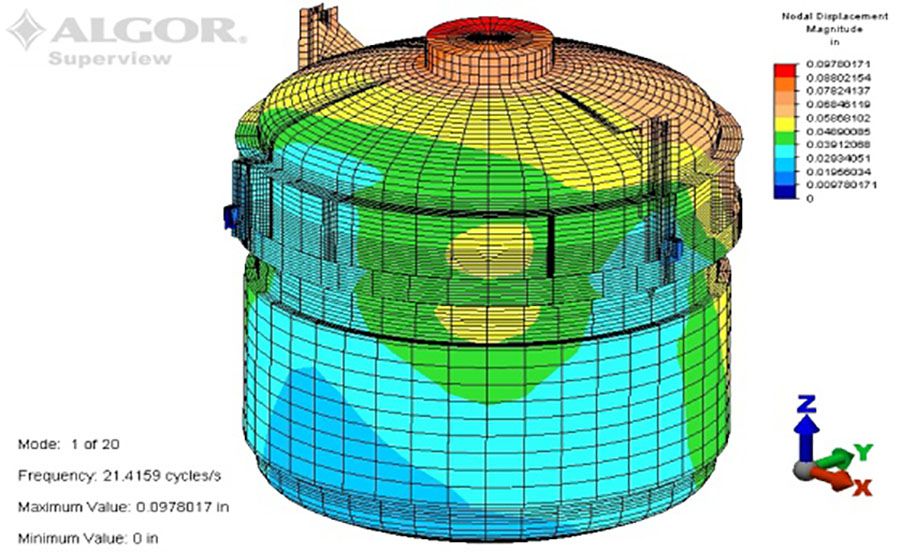

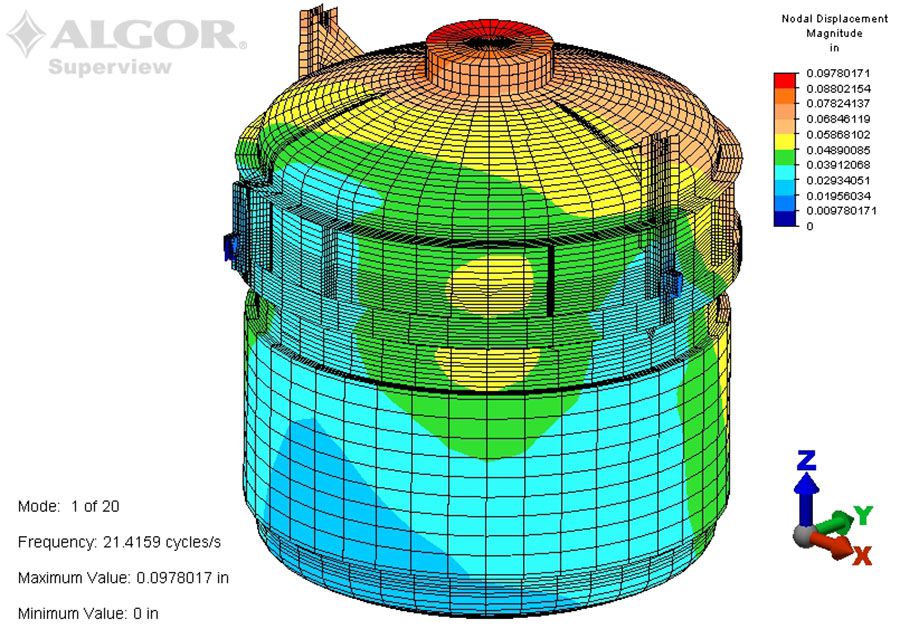

- Have extensive experience in using ASME Sections I, III, VIII Division 1 and Division 2 to design pressure vessels.

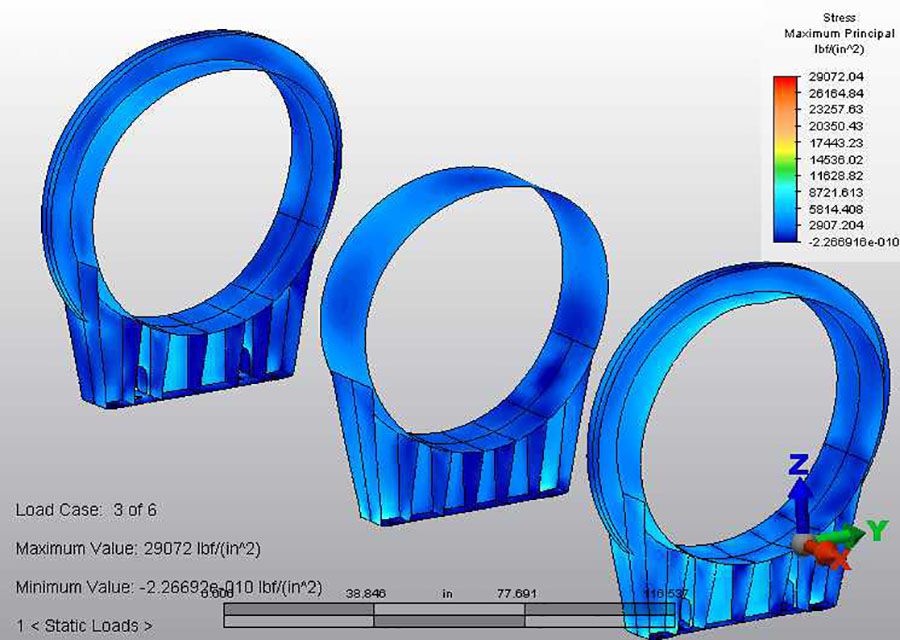

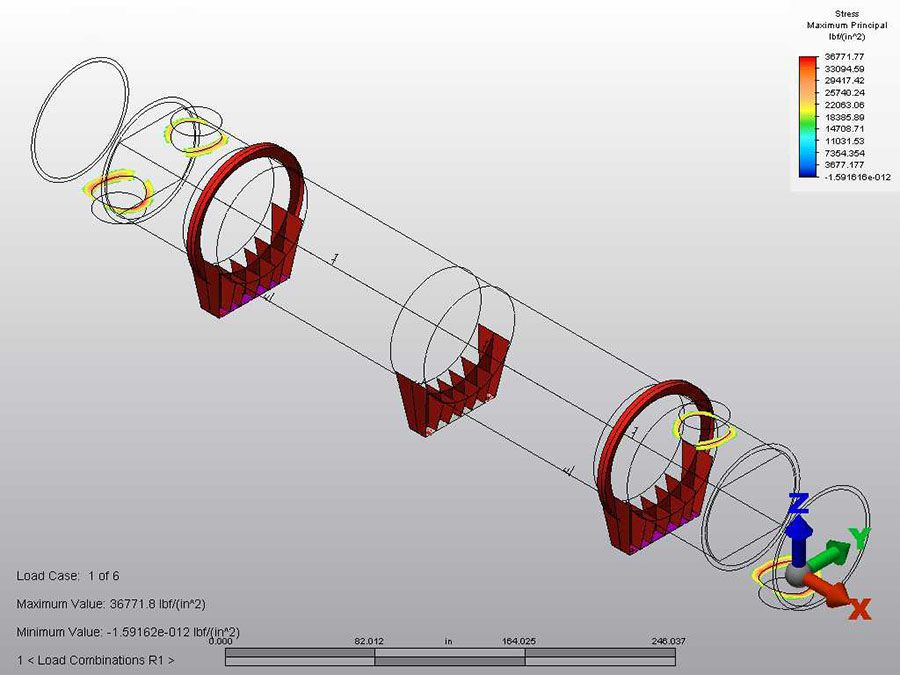

- Are Registered Professional Engineers, qualified to perform Design by Analysis per ASME Section III and Section VIII Division 2 and to certify the Design Reports.

- Work with User’s Design Specifications to produce custom designs, exactly fitting application requirements.

- Are active on ASME Code and TEMA Technical Committees.

- Design shell and tube heat exchangers for challenging thermal, hydraulic and vibration conditions using HTRI™ and ASPEN™ design software, custom calculations, and innovative baffle systems.

- Use building codes or customer supplied loads in conjunction with AISC 360 or N690 Structural Codes to design supports and lifting devices.

- Are involved with all areas of fabrication, including machining, welding, fixtures and heat treatment.

top

Joseph Oat Designs include the following:

- Heat Exchangers, for Nuclear Power Plant, Mining, Petrochemical and Refining applications.

- Both Self-Supporting and Guided Process Columns with Wind and Seismic loads.

- Tanks and Reactors with Lug, Saddle or Skirt supports.

- Special construction details for reactive metal cladding, high temperatures or high pressures.

- Steam Lifts and Air Lifts for nuclear waste processing vessels.

- Custom Flanges, Nozzles, Tubesheets and Expansion Joints.

- Filters, Strainers, Venturis, and other flow-control components.

- Lifting and Support Structures.

top