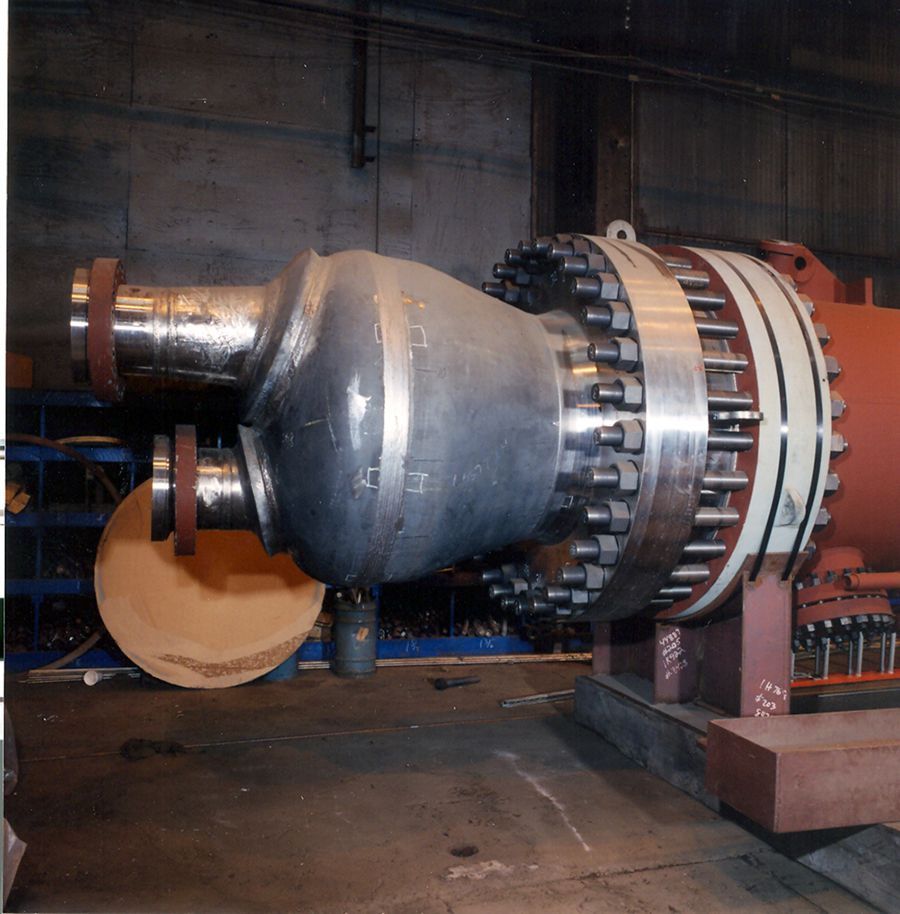

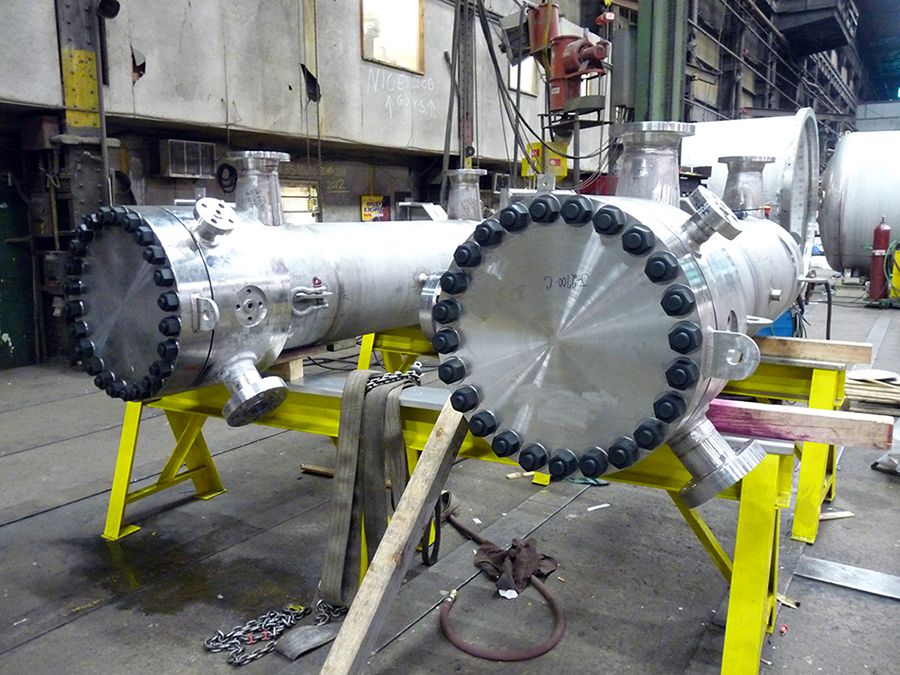

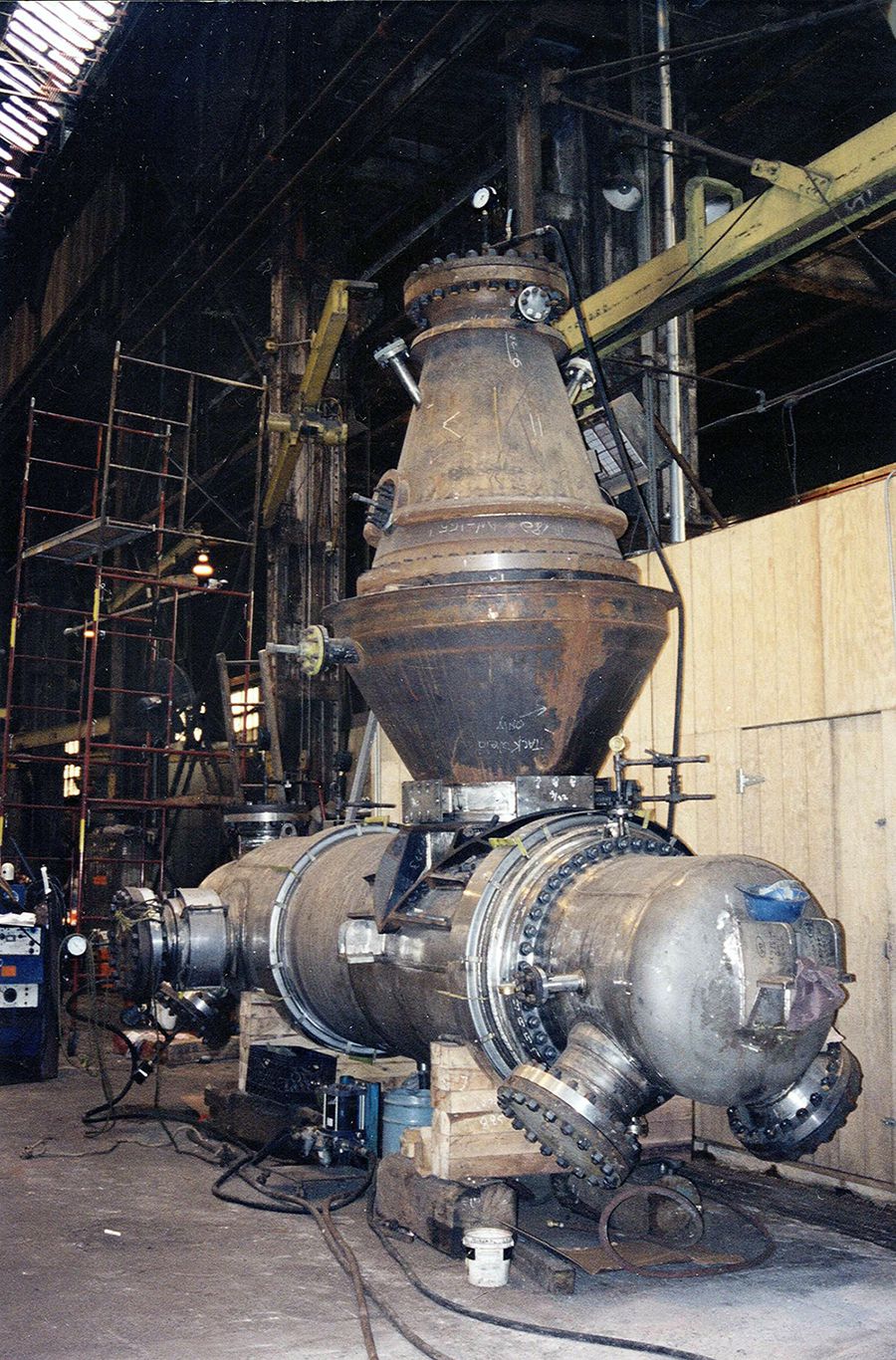

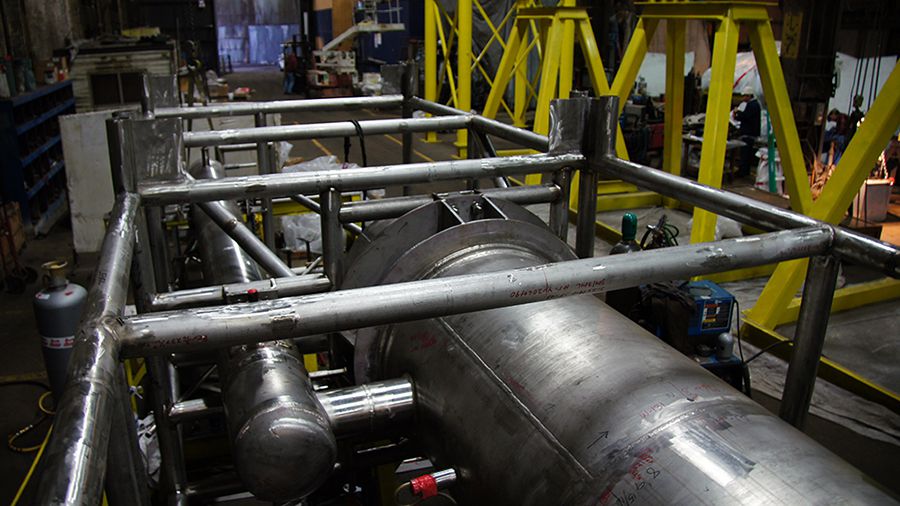

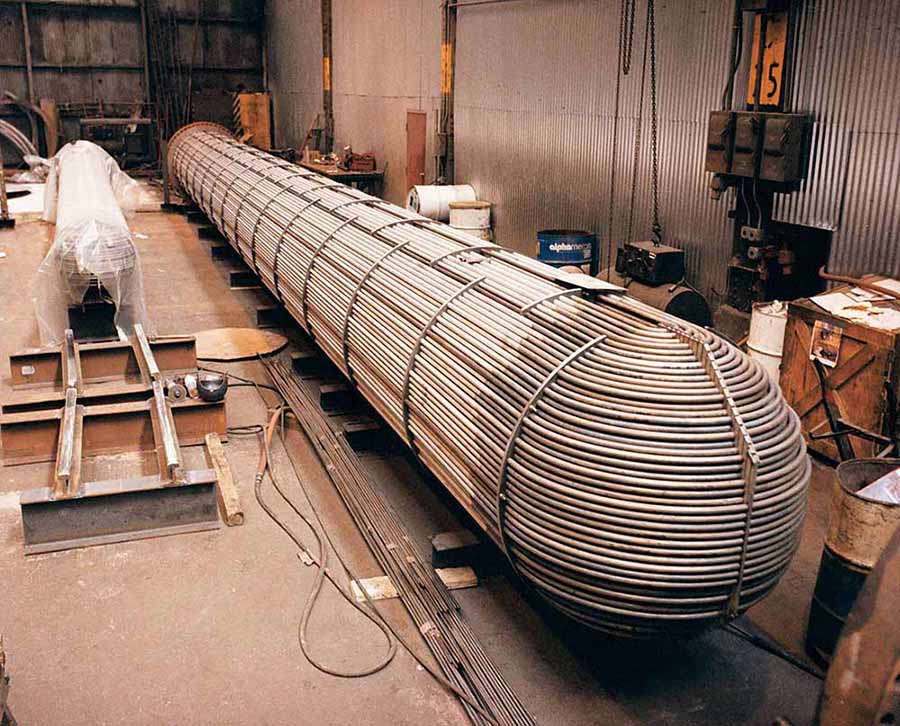

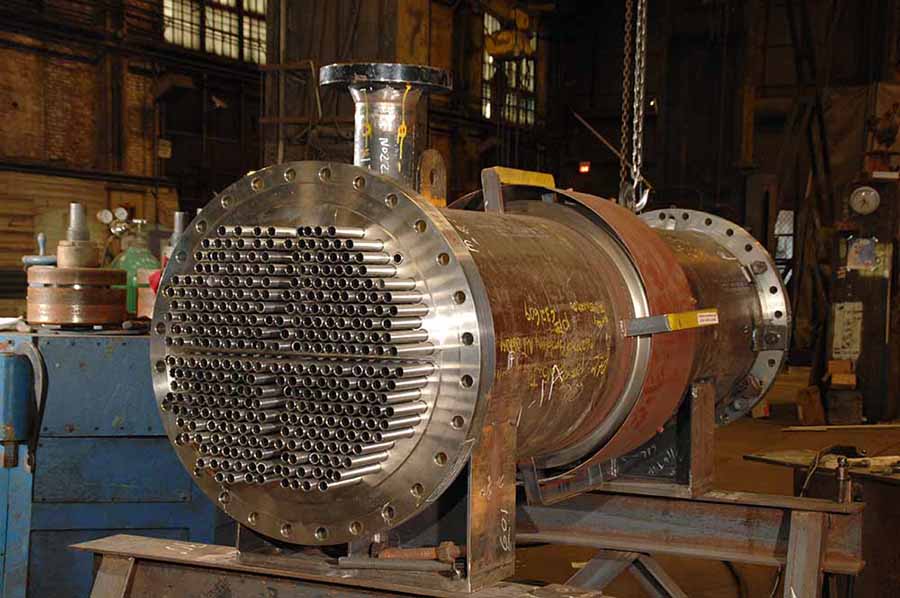

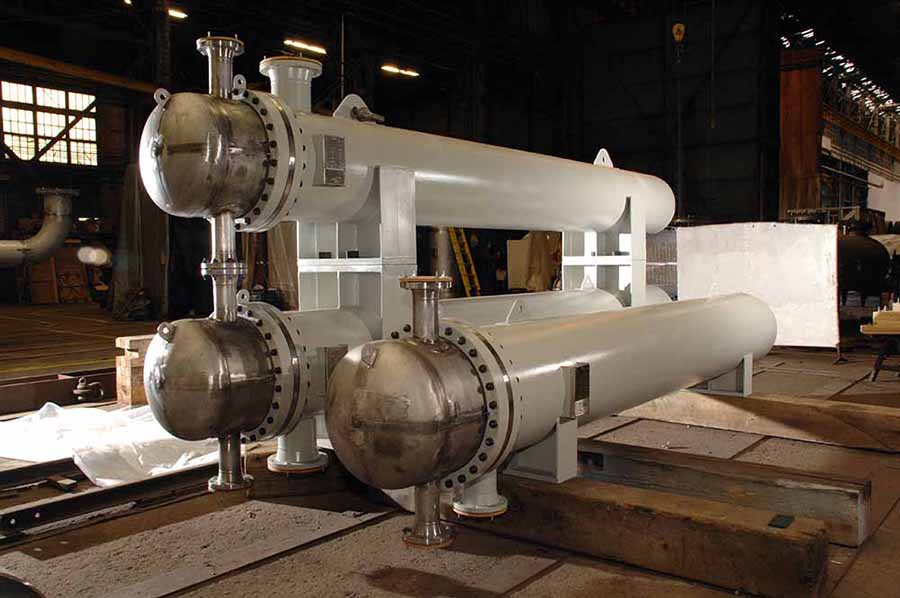

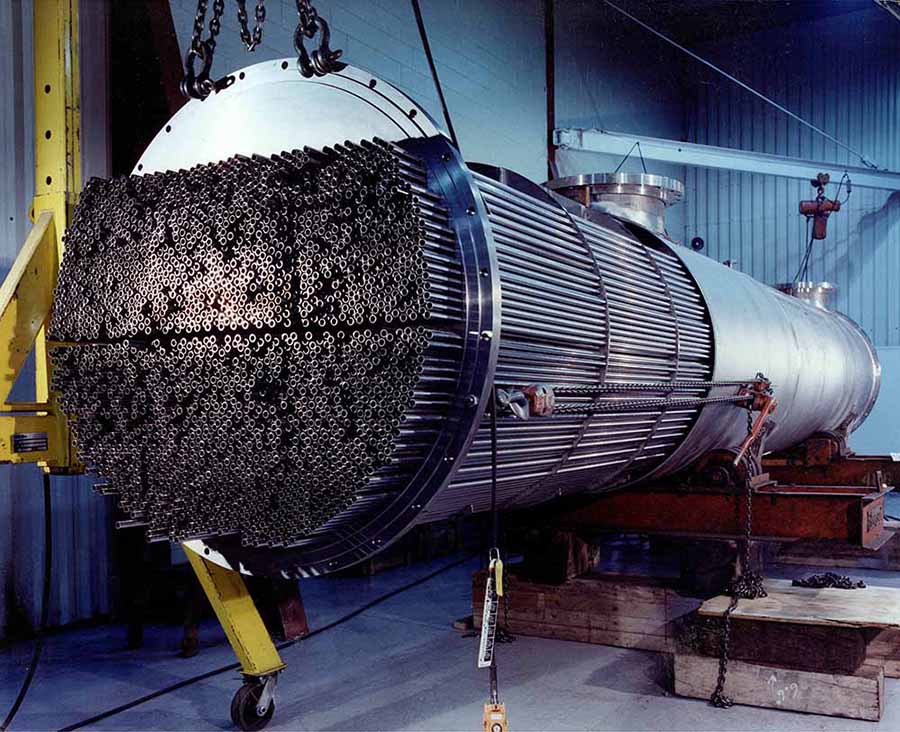

Shell and Tube Heat Exchangers

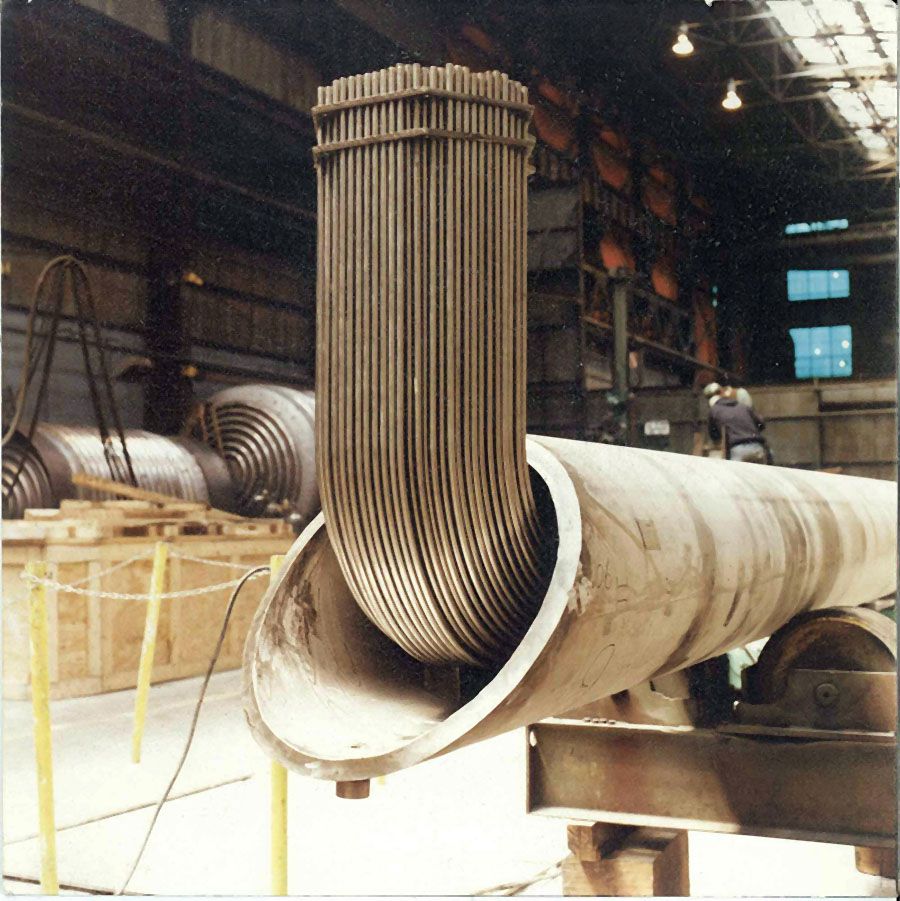

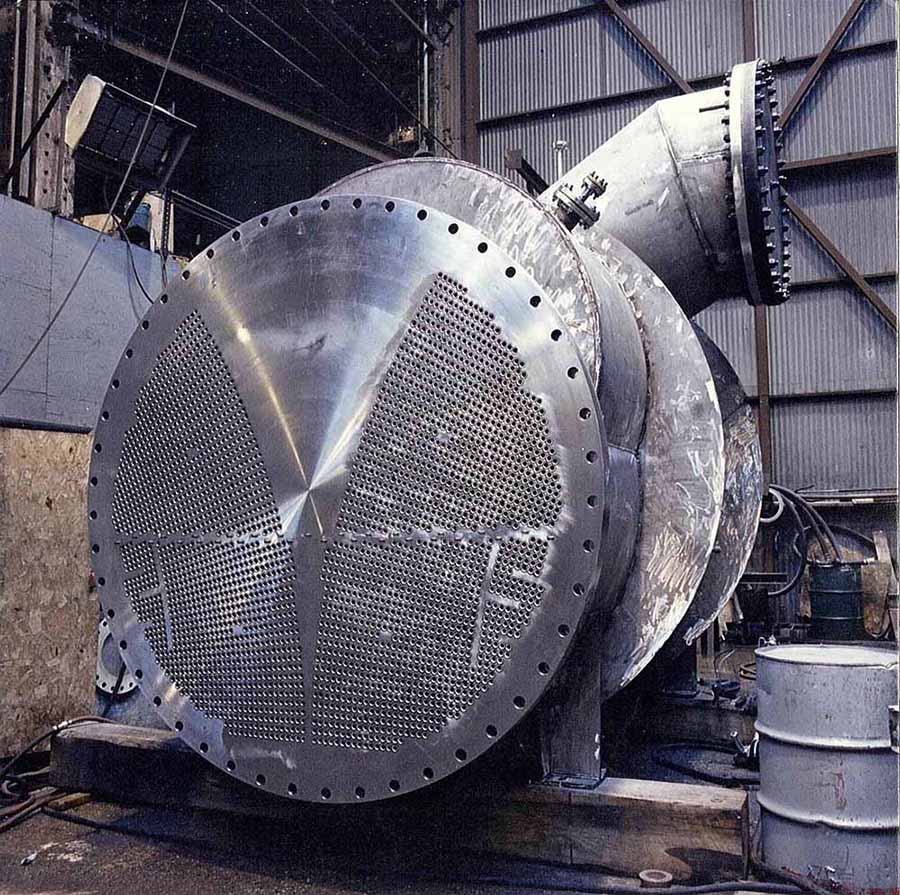

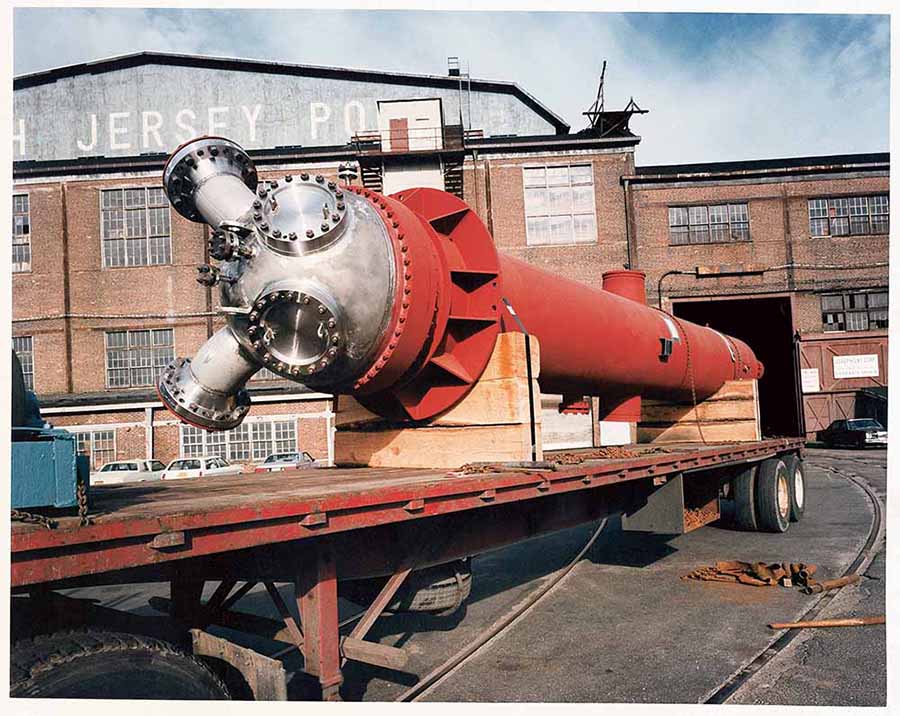

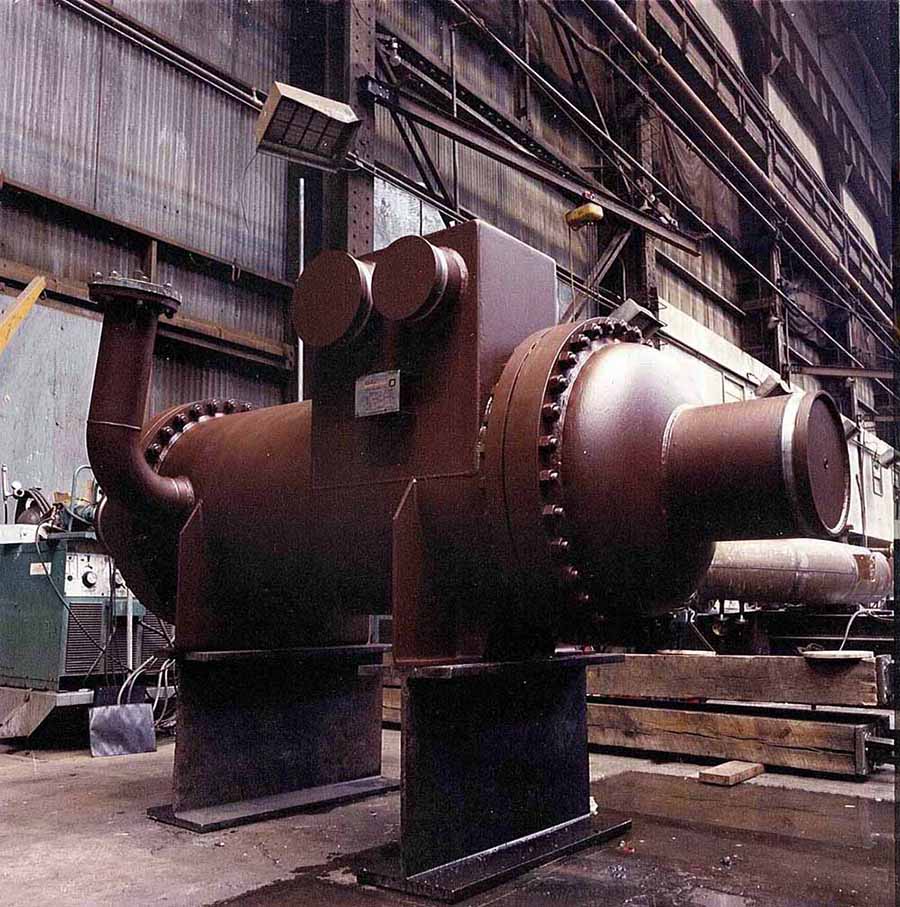

Joseph Oat’s experience and expertise in the design and manufacturing of shell and tube heat exchangers is well documented, and our renowned reputation in this art is well established internationally. Oat designs and fabricates heat exchangers in every configuration and size, from small units to units measuring over 144″ (3700 mm) in diameter and weighing up to 200 tons. Whether we perform a full thermal and mechanical evaluation and design equipment from customer raw data, or fabricate to “build to print” specifications, Oat provides high quality work and competitive pricing. Many of our heat exchangers have been in continuous service for over a half a century.

Utilizing sophisticated design software including but not limited to HTRI™ and Aspentech™, and the combined many decades of experience which our engineers have earned in this industry, the customer can be certain that they are receiving the latest state-of-the-art design. Our charter membership and active participation in TEMA provides us with access to the latest technology. In addition, our production department has a wealth of fabrication experience and has manufactured thousands of heat exchangers for virtually every chemical, petrochemical, and power application, including safety-related nuclear applications. Our ASME certifications, including ASME Sec I, III (all classes), VIII Div 1 and VIII Div 2 provide us with the opportunity to serve you in virtually any application where a shell and tube heat exchanger is appropriate, including applications involving cyclical service, highly corrosive applications, lethal service, cryogenic service, and radioactive service. We can also manufacture units to European standards, including PED.

Nuclear and Commercial Power

- Residual Heat Removal (RHR)

- Spent Fuel Pool

- Containment Spray

- Component Cooler

- Hydrogen Cooler

- Letdown

- Excess Letdown

- Regenerative

- Non-regenerative

- Oil Cooler

- Air Cooler

- Emergency Diesel Generator Jacket Cooler

- Chiller Condenser

- Bypass Condenser

- Steam Condenser

- RCP Motor

- Recirculation Spray Cooler

- Seal Water

- Steam Generator Blowdown

- Feedwater Heater

Industrial (Chemical, Refinery, Offshore platform, Pharmaceutical, Pulp & paper, Mining, LNG, etc.)

- Condensers

- Vaporizers

- Coolers

- Heaters / Preheaters / Superheaters

- Evaporators

- Boilers, Special Purpose

- Reboilers

- Calandrias

- Tubular Reactors